Industrially Made Paper Yarns – A Short History

PaperPhine’s Strong Natural Paper Yarn on a Vintage Bobbin – available online

The first technology to industrially produce paper yarns were developed in the late 19th century in Germany. Even though the processes have been refined over the time the initial technology is still in use today.

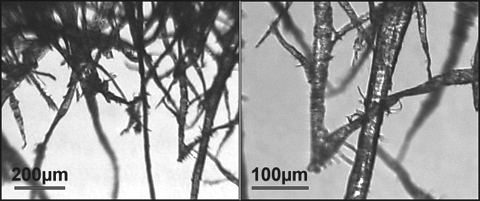

Cellulose fibres under the microsope. This is the raw material for a lot of paper yarns even though the fibres are not always as finely dissolved and “separated” as shown on this picture.

The paper used for making yarns (so-called spinning papers or Spinnpapiere) has to have long fibres therefore sulphate-papers (Sulfatpapiere) were mostly used. In those papers the cellulose fibres are not completly dissolved therefore the paper is stronger. The thickness of spinning papers can vary – the thinnest are like tissue paper, the thicker ones like thin printing paper. The thickness of the paper together with the breadth of the paper strips later determines the thickness of the paper yarn.

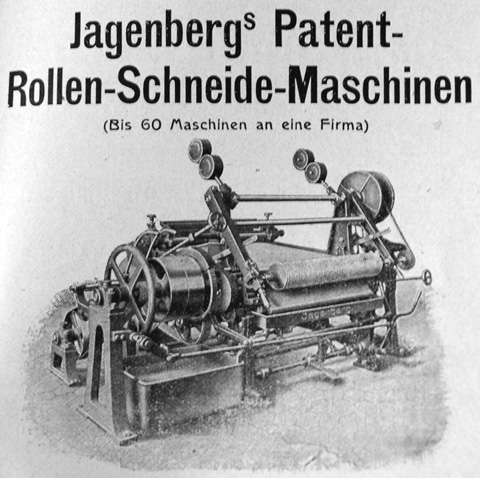

In the early 20th century there were still quite a few companies suppling the paper yarn industry with the necessary machines. This advert is for a German Paper-Strip-Cutter patented by Ferd. Emil Jagenberg.

In the early times of paper yarn production it was common that fine strips of paper were made with the help of special devices on the paper machine instead of cutting the paper later on. Up to about 1910 this kind of paper yarns were widely used and sought-after as an important subsitute for other yarns. Then the other variety – paper yarns spun out of dry-cut paper strips – became popular before disappearing into nearly complete oblivion in the 1950s.

During the years of the second World War it was also common to combine the paper with other materials. For these yarns (Textilosegarne) that were a necessity due to the lack of proper and sufficient raw materials, a fine layer of linen-, cotton- or flaxfibres was glued onto the paper before it was cut and spun. To my knowledge these yarns aren’t produced anywhere anymore.

PaperPhine’s Selection of Colored Paper Yarns in Reds and Yellow – available since today!

Today there are only very few paper yarn spinneries left in Europe that spin paper yarns out of rolls of papers coming from the big paper factories. Thicker yarns are then partially delivered to the dyeing mills where they are labouriously dyed. The thinnest yarns stay in the original color that is either white or a natural-brown.

The promised Short History of Handmade Shifu is not forgotten, only postponed a little. Also a description of the cutting- and spinning-process of industrial paper yarns is in work (too many interesting facts to collect and too little time, sorry). This is just a short summary of the whole history and development of industrial paper yarns. Due to its importance at certain times there are quite a few processes that were used etc. so the whole history is quite complex.

Most of my reference material is in German, therefore you find some German technical expressions in the text. If you have or know of reference materials in English or French I would be really grateful if you could get in touch with me, thanks!